In today’s competitive manufacturing landscape, companies are constantly seeking ways to improve efficiency and reduce costs. One area where significant gains can be made is in the coil slitting and packing process. By upgrading to an automated slitting coil packing line, manufacturers can enjoy numerous benefits, including increased productivity, reduced labor costs, and enhanced safety. In this article, we’ll explore the advantages of implementing an automated slitting coil packing line and guide how to make the transition.

2. What is an Automated Slitting Coil Packing Line?

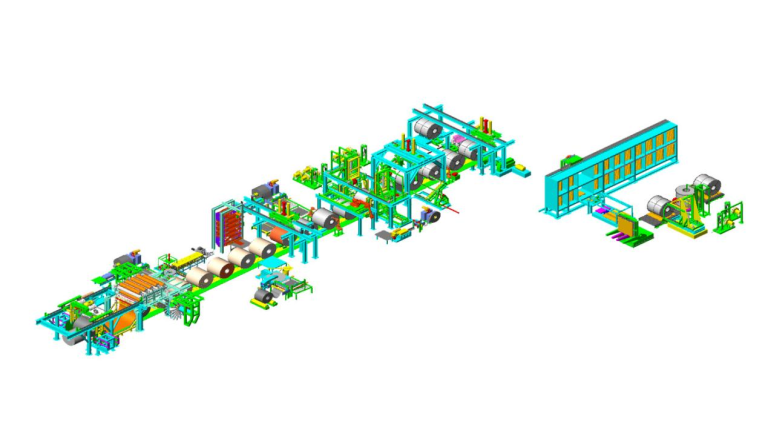

An automated slitting coil packing line is a fully integrated system designed to streamline the process of cutting and packaging metal coils. This type of line typically includes slitting machines, conveyors, coil-packing machines, and advanced control and monitoring systems. This high level of automation allows for more efficient and precise handling of the coils, resulting in increased productivity and reduced waste.

3. Benefits of Upgrading to an Automated Slitting Coil Packing Line

- Improved Efficiency

One of the most significant advantages of upgrading to an automated slitting coil packing line is the increased efficiency it brings. Automation allows for faster processing times and reduced downtime, as the system can operate continuously without the need for manual intervention. This ultimately leads to higher throughput and increased production capacity.

- Reduced Labor Costs

Automating the slitting and packing process can significantly reduce labor costs. With fewer manual tasks required, manufacturers can allocate their workforce to more value-added activities or reduce their overall headcount. Additionally, automation reduces the likelihood of human error, further enhancing efficiency and cost savings.

- Enhanced Safety

Safety is a top priority in any manufacturing environment, and automation can play a key role in reducing workplace accidents. Automated slitting coil packing lines eliminate the need for workers to perform potentially hazardous tasks, such as manually handling heavy coils or operating dangerous machinery. This results in a safer work environment and reduces the risk of injury-related downtime.

- Higher Quality Output

Automated slitting coil packing lines are designed to provide precise, consistent results, ensuring that each coil is cut and packaged to the highest standards. This level of quality control is difficult to achieve with manual processes and can ultimately lead to a better final product and increased customer satisfaction.

- Increased Scalability

As production demands grow, an automated slitting coil packing line can easily scale to meet increased capacity requirements. Additional equipment and conveyor systems can be integrated as needed, allowing for a seamless expansion of the line without significant downtime or disruption.

- Environmental Advantages

Automation can also contribute to a more environmentally friendly manufacturing process. By reducing waste and optimizing energy usage, automated slitting coil packing lines can help manufacturers minimize their environmental footprint and comply with increasingly stringent regulations.

- Easier Maintenance and Troubleshooting

Advanced control and monitoring systems allow for real-time tracking of equipment performance and easy identification of potential issues. This can lead to faster troubleshooting and reduced maintenance downtime, further boosting overall efficiency.

4. Key Components of an Automated Slitting Coil Packing Line

- Slitting Machine

The slitting machine is responsible for cutting the metal coils into the desired widths. Modern machines utilize advanced technology to ensure precise, consistent cuts and minimize waste.

- Conveyor Systems

Conveyors transport the coils between various stages of the slitting and packing process. They can be customized to meet the specific requirements of each facility and are designed to integrate seamlessly with other equipment in the line.

- Coil Packing Machines

Coil packing machines are responsible for securely packaging the slit coils for transport or storage. They can accommodate various packaging materials and can be configured to provide the desired level of protection for each product.

- Control and Monitoring Systems

Control and monitoring systems are the central nervous system of an automated slitting coil packing line. They oversee the operation of each component, ensuring that the entire process runs smoothly and efficiently.

5. How to Implement an Automated Slitting Coil Packing Line in Your Facility

Implementing an automated slitting coil packing line requires careful planning and coordination. Begin by assessing your current process and identifying areas where automation could provide the most significant benefits. Next, research equipment suppliers and select a partner with a proven track record in delivering successful automated systems. Finally, develop an implementation plan that includes thorough testing and training to ensure a smooth transition.

6. Conclusion

Upgrading to an automated slitting coil packing line can bring numerous benefits to manufacturers, including improved efficiency, reduced labor costs, enhanced safety, and higher-quality output. By investing in this advanced technology, companies can gain a competitive edge in the global market and position themselves for long-term success.

FAQs

- How much does it cost to upgrade to an automated slitting coil packing line?

The cost of upgrading to an automated slitting coil packing line can vary depending on factors such as the size of your facility, the complexity of the process, and the specific equipment required. It’s essential to work with a reputable supplier who can provide a detailed cost estimate and help you determine the potential return on investment.

- How long does it take to implement an automated slitting coil packing line?

The timeline for implementing an automated slitting coil packing line depends on factors such as the complexity of the project and the availability of equipment. In general, the process can take several months to a year or more, from initial planning through installation and testing.

- Can an automated slitting coil packing line be customized for my specific needs?

Yes, automated slitting coil packing lines can be tailored to meet the unique requirements of each facility. Equipment suppliers can work with you to design a system that incorporates the necessary components and integrates seamlessly with your existing processes.

- What types of materials can be processed using an automated slitting coil packing line?

Automated slitting coil packing lines can handle a wide range of materials, including steel, aluminum, and other metals. The specific capabilities of the line will depend on the equipment used, so it’s important to work with a supplier who understands your material requirements.

- How can I ensure the success of my automated slitting coil packing line project?

To maximize the success of your automated slitting coil packing line project, it’s crucial to partner with an experienced equipment supplier, thoroughly assess your needs, and develop a comprehensive implementation plan. Additionally, providing proper training for your workforce and conducting regular maintenance will help ensure the ongoing performance and efficiency of the system.