Molding quality control is a process that is used to ensure that the molds used in the manufacturing process are of the highest quality. This process begins with the selection of materials, and continues through to the final inspection of the molded product. In order to produce high-quality molds, it is important to have a clear understanding of the molding process and the factors that can affect product quality. In this blog post, we will discuss the steps involved in molding quality control, and we will outline some of the key factors that need to be considered.

Molding quality control begins with the selection of materials. The type of material used will have a direct impact on the quality of the final product. In order to ensure that only high-quality materials are used, it is important to work with a reputable supplier who can provide certified materials. Once the materials have been selected, they need to be prepared for the molding process. This usually involves cleaning and drying the material, as well as preparing it for injection by adding any necessary additives.

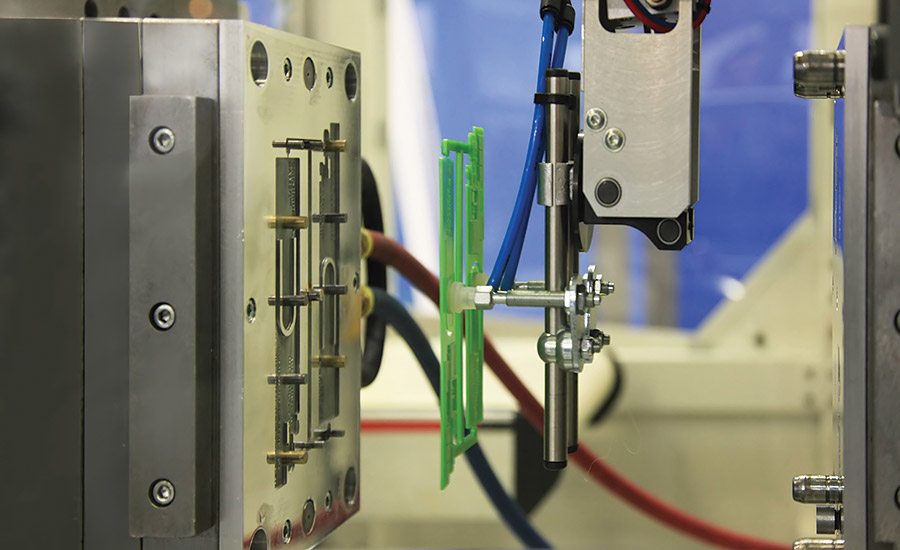

After the material has been prepared, it is time to start the molding process. The first step in this process is known as preheating, which helps to ensure that the material is at an ideal temperature for injection. Next, the material is injected into the mold cavity, where it is allowed to cool and solidify. Once the material has cooled and solidified, it is then removed from the mold and inspected for any defects. If any defects are found, they need to be corrected before the product can be released for sale.

Molding quality control is a critical part of the manufacturing process, and it is important to ensure that all molds are of the highest quality before they are used. By following the steps outlined in this blog post, you can help to ensure that your products are of the best possible quality. If you have any questions about molding quality control, or if you would like to learn more about how we can help you improve your manufacturing process, please contact us today. We would be happy to discuss your specific needs and requirements, and we can provide you with a free consultation. Contact us today to get started.

FAQ’s

What is quality control in injection moulding?

Injection moulding quality control is the process used to ensure that the molds used in the manufacturing process are of the highest quality. This procedure begins with the choice of materials and includes the last inspection of the molded good.

What are the moulding defects?

Molding defects can include flash, sink marks, warpage, voids, and more. For a complete list of potential defects, please consult your injection molding supplier.

How do you control quality in plastic injection moulding?

It’s critical to have a solid grasp on the molding process and the variables that may influence product quality in order to create high-quality molds. In this blog article, we’ll go through molding quality control procedures, as well as some of the key elements to consider.