It is a global, as his name indicates, leading tech company that provides solutions for automation in the PVC, aluminum, and wood industries. It is global because exports machines and spare parts to all four continents. Daser, with its technological improvements, principally contributes to the production of windows and doors. And plays a very important role in the Aeronautic, Automotive, and Ferroviarie industries.

Daser Global has more than twenty years of track record developing precise, accurate, and speedy automated machines. The technology produced by Daser helps companies to ease storage, cutting, machining, welding, cleaning, assembly, glazing, deformation, and blent. These machines are developed by an expert team of engineers and programmers. They come with detailed instructions and are user friendly.

With Daser Global machines you can boost productivity and enhance efficiency. All the machines are robust and have longevity. If anytime the machine is not working at one hundred percent, then Daser can provide you with all the spare parts to make it work at its full speed and performance again. They also provide support for installation and, if it is needed, programmed maintenance.

Why choose Daser Global?

Expertise, experience, and reliability are the three words that most describe Daser. Currently, the technology industry brings upgrades almost every day. So, customers seek flexible and fast solutions; and it is what Daser provides. Their machinery is designed with compatibility to add posterior upgrades. High prestige partners endorse Daser, their allies are BDM – BJM DUBUS, MECAL, KABAN, and LEMUTH. All of them are leading and cutting edge companies in automation machinery all over the world.

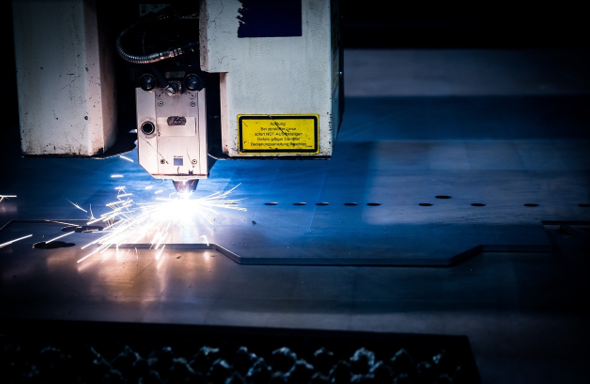

Automation is a must for any industry, it may seem expensive at first but the inversion capital can be quickly recovered. Automation is a proven method to increase productivity and reduce labor costs. There are three types of automated machines, those that are fully automated, those that are fully manual, and automated machines that require some manual intervention to meet specific goals. This intervention is usually a setup and configuration of the machine’s software. The operator sends commands through a computer to give instructions to the machine and make the hardware move.

The precision in automation is achieved through sensors, scanners, and programable logic controllers. Think about the automotive factories that perform the assembly of a car from end to end, for example. This procedure will take a lot of effort and workforce to be done without machines, and it also means that will take a longer time to be completed and will cost much more money. But with Daser machines it can be done easily, continuously, and without defects.

Which are the cons of Automated Machinery?

Well, by now we talked about all the pros of Automated Machinery. But being realistic, everything has cons. At least some. The startup of an automated factory or the transition from a manual to an automated one needs trained and qualified workers. Some factories have a hard time finding qualified workers that know to handle these machines or are capable to learn to do it. One machine will not be enough to reach the goals of most factories, if you are thinking to invest in automation then consider that you will need several machines that interconnect and work together to develop your products. As we said before, you will need a high initial capital to start designing and fabricating your desired machines. But also as we said before, the costs are really worth and it is one of the best proven investments. Another con of automated machinery is that it needs maintenance more frequently than manual machines.

More information: https://daserglobal.com/contacto/