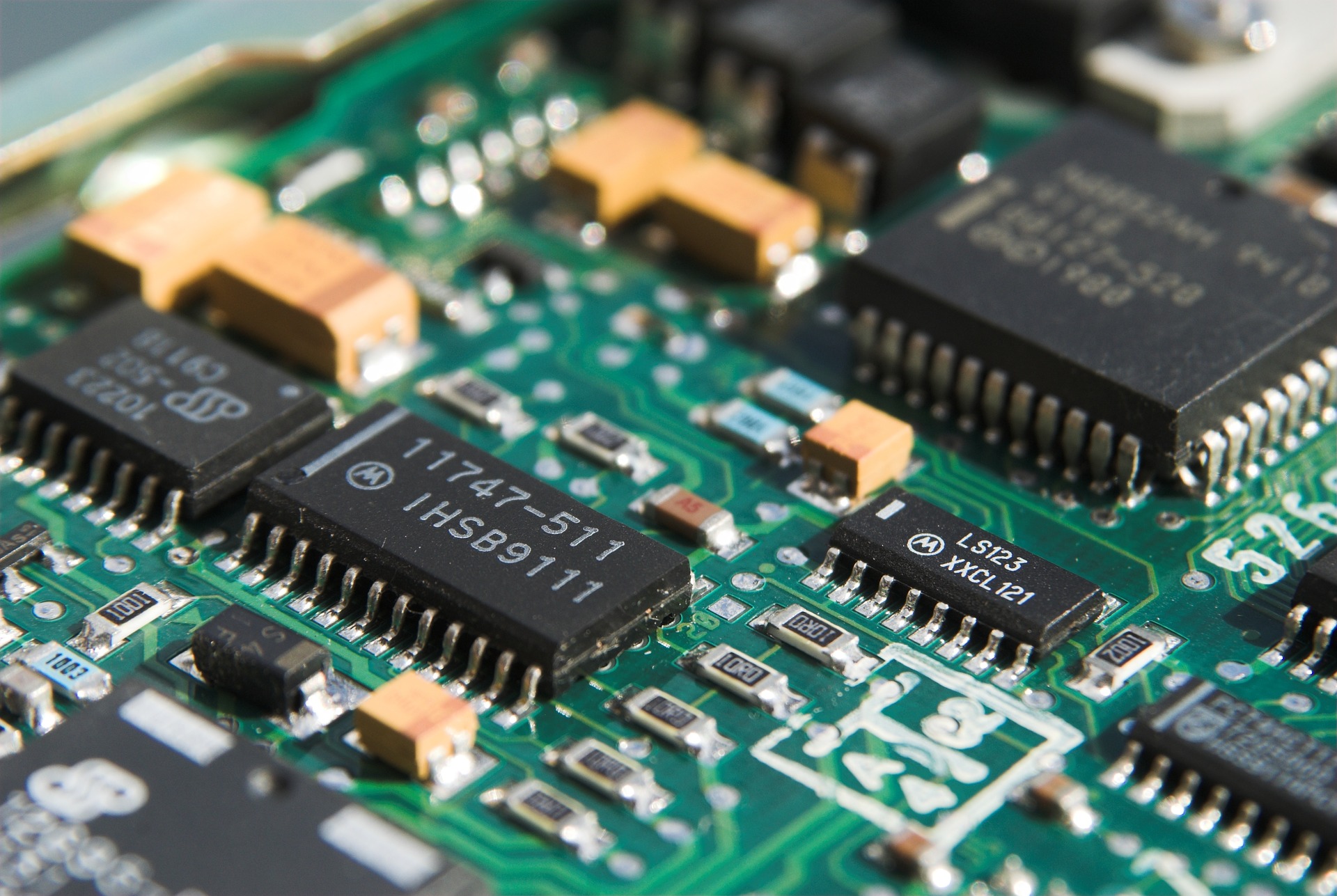

There are two materials to make PCB board: ceramic-filled polytetrafluoroethylene and woven glass-reinforced composites, which are both made of the same materials. These boards can be used in RF solutions for communication and space projects. Also, PCBs are one of the most important elements for aerospace manufacturing.

When making this circuit board, it is essential to keep costs down, so keep that in mind. For professionals, it is usually a cheap way to get things done. This laminate has a lot of ceramic, giving it the best value.

Laminates with low dielectric loss are suitable for radiofrequency and microwave work. One of the significant benefits of these boards is that they don’t lose a lot of electricity. Because of the materials used to make PCB laminate, it has a low loss of dielectric sound.

Dielectric constants in a wide range: PCB has a wide range of dielectric materials, making it suitable for many different things.

It has a low dissipation factor, which makes it a good insulator because it doesn’t let the heat get through to the outside. An effective insulator device has a common way of dissipating heat.

High workability: PCB stays the same size when it gets hot. Experts use this circuit board for things that are likely to be exposed to a wide range of conditions.

Low moisture absorption rate: This board has a low moisture absorption rate. As a result, it can be used in wet places. On the other hand, moisture makes PCBs less durable, so a PCB that doesn’t need a lot of humidity is ideal.

Essential things to think about when making hybrid products:

To make hybrid PCBs, such as the rf 35 PCB, you need to think about certain things.

Drill parameters are essential to check because they can change how well a hole is made. Moshe stack-up materials control the feeds and speeds of the drill and the rates and feed used to produce hybrids. Like those that make a lot of heat, some parts can make things bend. Contact the best Taconic PCB manufacturer, for your benefit.

Compatibility: The components of the hybrid stack-up must be compatible with each other during the lamination process. Some materials need more heat and pressure during the lamination process than others. Before you use a resource for construction, always check the specifications to make sure it can be used for that.

After the hole is drilled, the next step is to prepare the hole wall. Each group might have its own set of rules for doing things. On the other hand, to get 100% accuracy, you need to improve the method for each item.

Conclusion

Makes high-frequency PCBs board means that can be used for many different things. PCBs have a wide range of dielectric constants, very little dissipation, and very little loss of electrical signals. Weaved glass is used to make these laminates stronger. Thermodynamic, mechanical, and electrical qualities are all excellent, as well. All shapes and sizes can be found on PCBs made with a board.