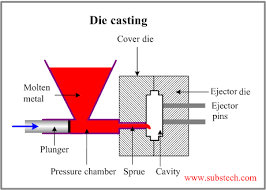

Die casting is a far reaching non-disposable method in which metal are constrained into the form hole under high tension. Die casting mold that are known as dies can be utilized over and over to deliver castings in an assortment of sizes, shapes and divider thickness. The form depressions are planned with multifaceted plans that empowers in delivering complex shapes with precision, surface completion and appeal..

History of Die Casting

In the beginning of die casting just low-pressure infusion strategy was utilized, yet today high-pressure casting procedures like crush casting and semi-strong die casting techniques are use to project in excess of 4500 pounds for every square inch. At first, just tin and lead were die station, yet presently magnesium, copper and other composites are additionally to project utilizing this profoundly well known cycle.

Die Casting Process

In this cycle liquid metal or different materials are constrained, under high tension into the depressions of the steel shape. Dies are two section shape that are made of compound instrument steel – The fixer die half and the ejector die half. The die or form is created with the impression of the part that is to projected. There are four kinds of dies:

Single pit to deliver one part

Numerous cavity to create various indistinguishable parts

Unit die to deliver various parts all at once

Mixes die to create a few distinct parts for a gathering

The liquid metal is infused into the die under high tension and high velocity, which helps in delivering a casting that is smooth and exact as the first shape. The tension is kept up with on the shape until the hot metal cements. At the point when the metal is solidified, the die is opened to eliminate the casting.

There are a few minor departure from the essential interaction that can be utilized to create castings for explicit applications. These include:

Crush casting – A strategy by which liquid composite is projected without choppiness and gas entanglement at high strain to yield superior grade, thick, heat treatable parts.

Semi-strong embellishment – A strategy where semi-strong metal billets are cast to give thick, heat treatable castings with low porosity.

Compounds utilized

Aluminum, copper, lead, zinc and tin based compounds are overwhelmingly utilized in die-casting.

Computerization

In present day, modern die casting machines are utilized that guarantees reliable quality control. Each machined die-casting varies in the strategy in which liquid dinner is filled the die. Computerizations are utilized to grease up dies, empty the metal into the chamber, and so on Two cycles called the hot chamber and the virus chamber strategies are utilized for die casting.

Applications

Die casting is generally appropriate for casting medium measured parts with complex subtleties. Die-casting is the biggest casting method that is utilized to fabricate buyer, business and modern items like autos, toys, portions of sink fixture, connector lodging, gears, and so on Most die castings are done from non-ferrous metals like aluminum, magnesium, and so on

Benefits

Practical cycle that can be utilized for a wide scope of perplexing application

Parts have longer assistance life, dimensional exactness and close resistance

Post machining can be completely wiped out

A cycle that can be completely computerized

Form can be use over and over.

Burdens

Casting weight should be between 30 grams.

Casting should be more modest than 600 mm (24 in)

High introductory expense.

Restricted to high-ease metals.

We desire to make a valuable asset for uniquely designed parts and materials. With wide foundation in casting, post assembling, painting and plating processes, we give the specialized data and news relating to project, fashioned material and machined strategies. Our great English talking engineer will help you to make the legitimate plan to your greatest advantage. We have no plan other than assisting our clients with working on their item and lessen their assembling cost. die casting organizations, aluminum die casting organizations

reference: http://wishsino.com/product-category/product-design-and-development/