Injection molding has modified the performance of producing lots of the goods which you use each day. From the toothbrush which you use withinside the morning to the plastic fork, you used to devour your lunch. Even the shades which you put on have been probably created by the usage of plastic injection molding.

Plastic injection molding machines took place withinside the 1930s. They have furnished an extra green and effective technique of mass-generating merchandise that we use every and each day. Plastic mildew injection works by heating a plastic cloth and injecting it right into a mildew hollow space. This is good due to the fact it could create more potent and extra unique merchandise. Previously, the method maximum probably concerned big quantities of plastic cloth that have been stamped or reduced. This allowed for wasted plastic and decrease quality. Mold injection permits any leftover plastics to be melted once more and reused.

A Molder`s POV

I were withinside the area of Custom Plastic Injection Molding for approximately 11 years now as of the writing of this article. I am presently operating as a Process Engineer, which I even have executed for approximately 5 of my 8+ years withinside the area of injection molding and I even have basically labored for molders that have been concerned withinside the car area.

Plastic injection molding, by definition, is the method of injecting plastic right into mildew (or mildew in European circles), cooling the plastic, ejecting it from the mildew, and packing the completed product on the market to the customer.

This sounds easy and in it is the simple shape it is, however the method concerned with making all this occur is really pretty complicated. Plastic may be injected into the mildew with low strain, however, usually is executed below excessive strain upwards of 30,000 PSI hollow space strain.

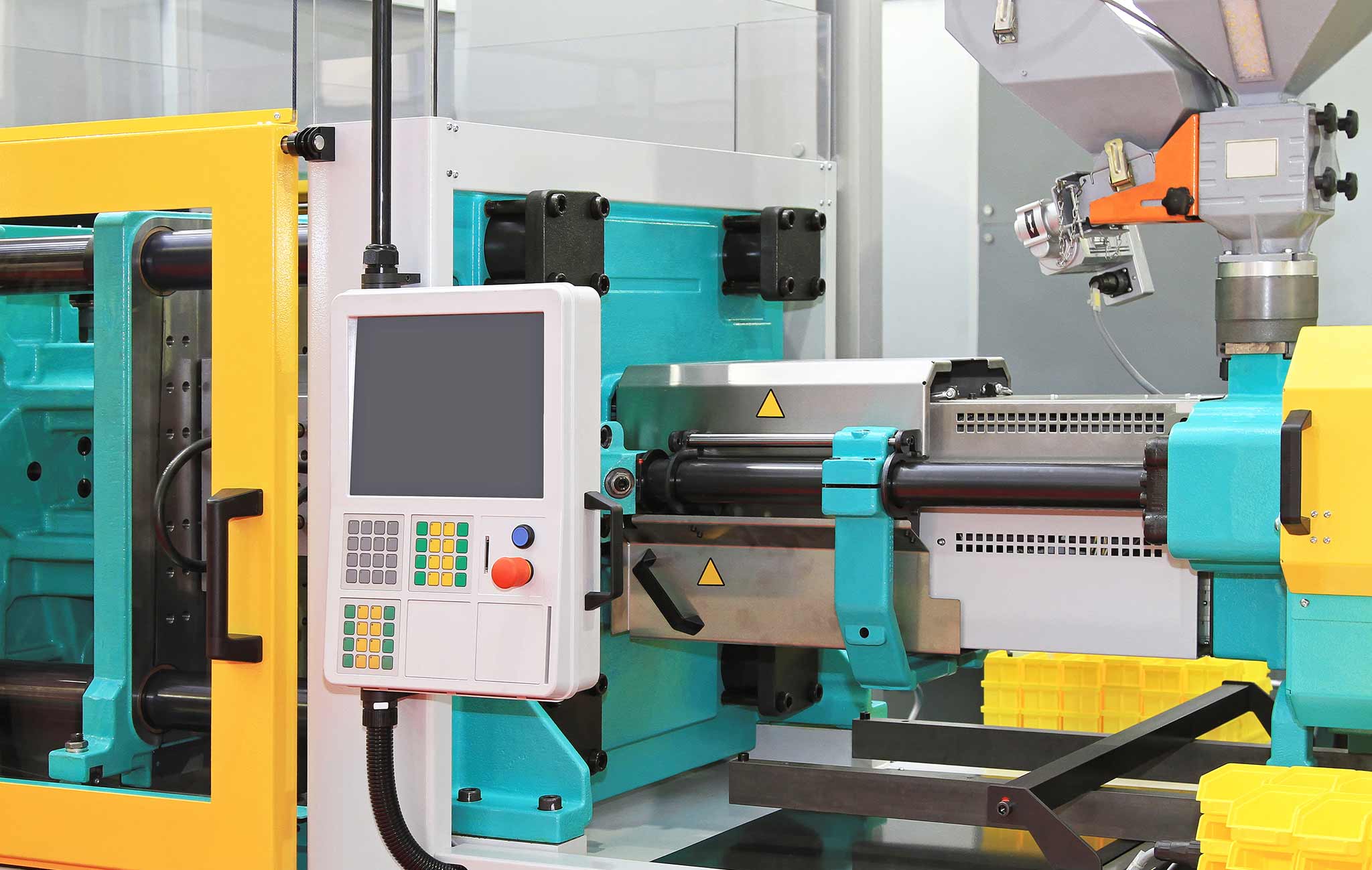

There are many various styles of injection molding and as many unique styles of plastic injection molding machine to go along with it. Some of the extra not unusual place styles of plastic molding are well-known mildew injection, insert molding, plastic extrusion, blow molding, multi-color or cloth molding, stack molding, and rotary molding simply to call some. There are custom plastics as well, from not unusual place each day plastic resins to the extra distinctive engineering grade resins utilized in maximum cars today. There is even injection molding grade “metals” being experimented with and used in those days.

There are many styles of injection molding machines all made for unique purposes. There are the usual horizontal injection molding machines which vary in length from some heaps all of the manners as much as 9000 heaps and extra. You should power the vehicle among the platens of a press that big. Vertical injection molding machines are frequently used for insert molding (despite the fact that this may additionally be executed horizontally) and percentage a not unusual place cowl with ejection halves of the mildew. This permits for de-molding and loading of inserts in a single 1/2 of, at the same time as the opposite 1/2 of generating the subsequent shot of elements. There also are 3 shot injection molding machines for generating multi-color or multi-cloth elements which include lenses for tail lighting and tool shift knobs with a difficult plastic internal center and a smooth vinyl out covering. The most up-to-date machines are “all electric powered versions” which stray from the usual hydraulic injection machines used now for years. These injection molding machines are tons extra green and repeatable than their hydraulic cousins are.

The simple steps to generating a plastic injection molded element on a stand injection molding device are:

- Heating the plastic resin to the desired variety of the product being used.

- Developing the shot length via the use of a reciprocating screw which conveys the melted plastic to the front of the screw.

- Injecting the plastic into the mildew below strain to fill the hollow space of the mildew.

- Packing the plastic to create a complete element in the mildew.

- Cooling the plastic withinside the mildew via using cooling channels maximum generally with water.

- Ejecting the cooling element from the mildew.

- Repeating the method again and again once more.