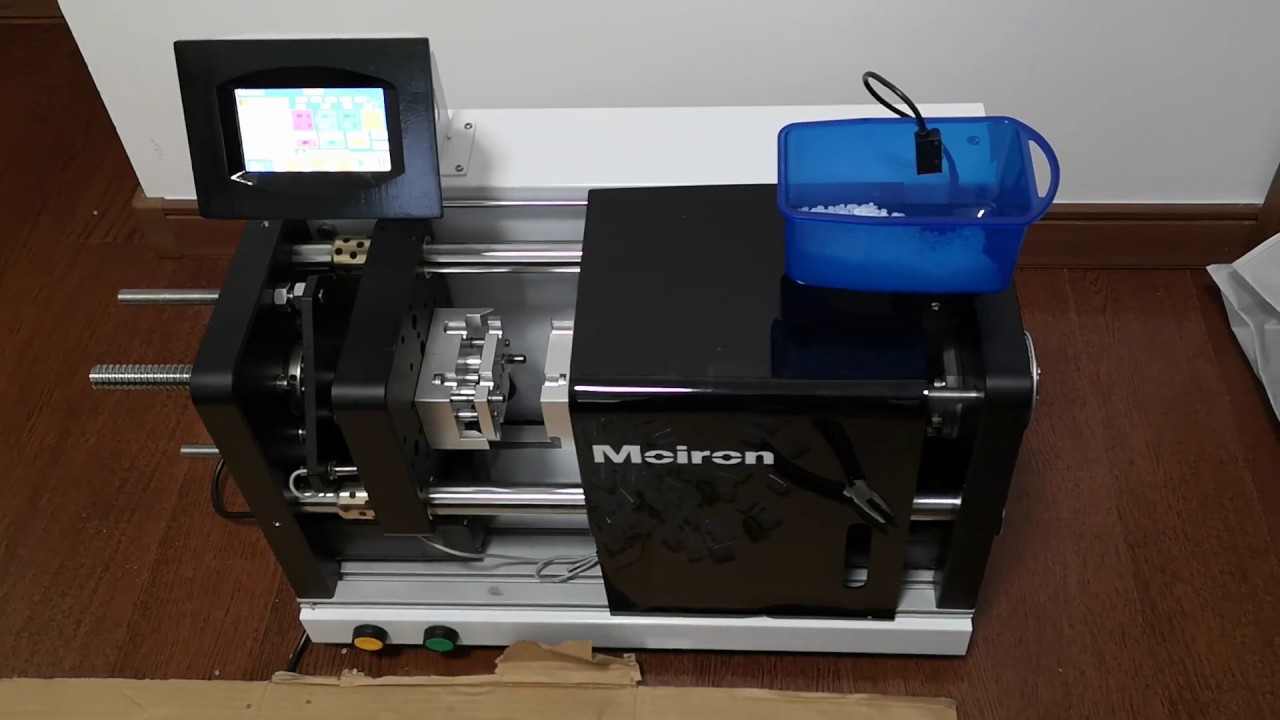

We will give you a brief introduction to the Desktop Injection Machine. This machine is used for plastic injection molding and has many benefits for its users. The desktop injection machine will help you make parts for your projects quickly, easily, and cost-effectively.

The desktop injection machine for plastic injection molding

You may have heard of the Desktop Injection Machine or DIM. If you haven’t, the DIM is a plastic injection molding machine that can be used at home by hobbyists and small businesses to create parts for their projects. The DIM works by heating plastic pellets to about 350 degrees Fahrenheit to melt them into liquid form. Then, it injects this melted plastic into a mold that contains your design! You can use different types of plastic depending on what needs to be made (such as ABS or PETG) and choose from molds with different shapes (like square tubes).

The best part? After building your custom-designed piece using the Desktop Injection Machine, you’ll only spend roughly $30-40 dollars per pound of material! So, if you want something made of cheap materials like ABS. This may be perfect and gives users the freedom to choose which materials. No longer worry about whether one product can work better than another – because everything here is good.

How does the Desktop Injection Machine work?

The Desktop Injection Machine is a 3D printer. It uses plastic filament to make parts, which can be used for various applications. The Desktop Injection Machine first downloads a design file from Thingiverse and then places it into the machine’s SD card slot. Once you’ve done this, press start and watch as your part is created before your very eyes!

The most significant limitation of this machine is its size; you won’t be able to incorporate any large parts into your designs with this printer due to its limited build volume (10 x 10 x 10 cm). But this machine should fit nicely into your workspace if you’re looking for something small enough for school projects or hobbyists’ workshops.

How to make parts from the Desktop Injection Machine?

We’re not going to lie: the Desktop Injection Machine is easy to use! It comes with a user guide that walks you through each process step, so you don’t have to worry about what you’re doing.

Setting up your injection molding machine is also very straightforward. You assemble all its parts and plug the mains power cord into an outlet – that’s it!

Maintaining this desktop injection molder machine is just as easy as setting it up. No complicated tools or instructions are needed for maintenance; you’ll need some basic cleaning materials and time to clean out any plastic residue inside the machine after use.

Suppose something goes wrong with your Desktop Injection Machine. Disassembling and reassembling it should be relatively straightforward because there aren’t any complex parts involved with this model.

How many designs can be made from the Desktop Injection Machine?

One of the best things about the Desktop Injection Machine is that it can be used to make many different parts. This machine can produce small, extensive details and features for various industries and applications. It also allows you to create new designs based on your imagination.

You can use this tool to build products for specific purposes, such as custom molding or an injection-molded part explicitly designed for your business or organization’s needs. The desktop injection machine has many applications today, making it a valuable tool for anyone who wants to create customized products at home or in a workplace setting.

What are the limitations of the Desktop Injection Machine?

While the Desktop Injection Machine is an excellent tool for small-scale production, there are some limitations. The machine has a maximum 30 ml capacity and can only fit one sample at a time. It also takes up quite a little space in your lab or office. If you want to make larger batches of products with this machine, it may not be the best option for you!

The desktop injection machine is ready to help you launch your fabrication lab.

The desktop injection machine is an easy-to-use, low-cost solution for your fabrication needs.

-It’s an affordable way to get started in 3D printing and other types of fabrication.

-The desktop injection machine is ready to help launch your lab or startup!

-You can learn the basics of this technology in a few hours at a local maker space or school.

So let’s summarize

The Desktop Injection Machine is a great way to get started in the world of injection molding. Although it has limitations, the machine offers a lot of value at an affordable price. With the proper knowledge and equipment, you can take advantage of its benefits for years to come!

Read on Googdesk.com