The concept of a MOPA (Master Oscillator Power Amplifier) fiber laser was first proposed in the early 1990s as a way to improve the performance of fiber lasers. These lasers use a single-mode fiber as both the oscillator and the amplifier, allowing for better beam quality and higher efficiency compared to traditional fiber lasers. MOPA fiber lasers were initially developed for military and aerospace applications, but have since been adapted for use in a wide range of industries.

In the early 2000s, MOPA fiber lasers began to gain widespread adoption in the industrial sector for applications such as laser marking, laser cutting, and laser welding. As the technology has continued to improve, MOPA fiber lasers have become increasingly popular due to their high efficiency, excellent beam quality, and versatility.

Today, wholesale mopa fiber laser manufacturer produces MOPA fiber lasers that are widely used in a variety of applications, including material processing, medical devices, and scientific research. The development of MOPA fiber lasers has significantly advanced the capabilities of fiber lasers and has led to their widespread use in a variety of industries.

MOPA (Master Oscillator Power Amplifier) fiber lasers are a type of laser that uses a single-mode fiber as both the oscillator and the amplifier. These lasers offer a number of advantages over traditional fiber lasers, including improved beam quality, higher efficiency, and greater versatility.

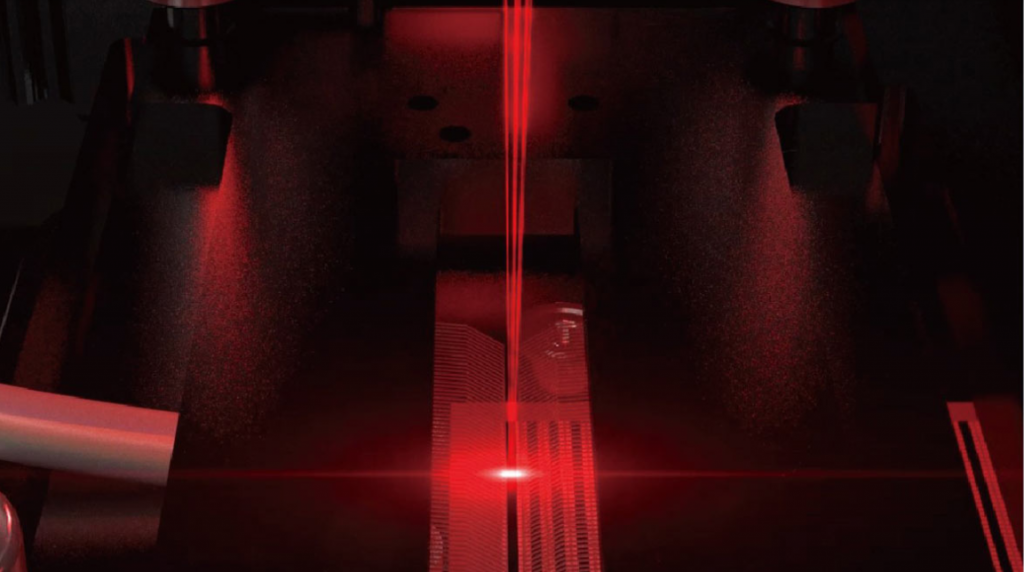

One of the primary capabilities of MOPA fiber lasers is their ability to generate a high-quality beam of light. These lasers produce a beam with a high degree of spatial and temporal coherence, resulting in a beam that is highly focused and collimated. This makes MOPA fiber lasers ideal for applications that require precise and accurate beam delivery, such as laser cutting and laser welding.

In addition to their beam quality, MOPA fiber lasers are also highly efficient and reliable. These lasers have a long lifetime, making them a cost-effective choice for applications that require a continuous beam of light over an extended period of time.

MOPA fiber lasers are also highly versatile and can be used in a wide range of applications, including material processing, medical devices, and scientific research. These lasers are available in different wavelengths and power levels, allowing customers to choose the best product for their specific application. Many MOPA fiber laser manufacturers also offer customization options to meet the specific needs of their customers.

Overall, the capabilities of MOPA fiber lasers make them a popular choice for a variety of scientific and industrial applications with the below-mentioned advantages.

High beam quality: MOPA fiber lasers produce a beam of light with a high degree of spatial and temporal coherence, resulting in a beam that is highly focused and collimated.

Efficiency: MOPA fiber lasers are highly efficient and have a long lifetime, making them a cost-effective choice for applications that require a continuous beam of light over an extended period of time.

Reliability: MOPA fiber lasers are highly reliable, making them a popular choice for many scientific and industrial applications.

Versatility: MOPA fiber lasers can be used in a wide range of applications, including material processing, medical devices, and scientific research.

Customization: Many MOPA fiber laser manufacturers offer customization options to meet the specific needs of their customers.

High power output: MOPA fiber lasers can produce a high-power beam of light, making them ideal for applications such as cutting and welding.

Precision: MOPA fiber lasers are highly precise, allowing for precise cutting and drilling of materials.

Non-contact processing: MOPA fiber lasers can be used for the non-contact processing of materials, making them ideal for delicate or sensitive materials.

Speed: MOPA fiber lasers can process materials at high speeds, making them ideal for high-production environments.

Safety: MOPA fiber lasers are generally safer to use than other types of lasers due to their low power output.